OUR OPERATIONS IN NUMBERS

- 3 privately owned production plants located in Athens and Thessaloniki

- Over 42 proprietary manufacturing operations and 55 CNC MACHINES

- 245 employees

- Serving over 500 customers annually

- Manufacturing over 97,500 different products per annum

- Processing annually over 6,500 tons of metal

OUR MANUFACTURING CAPACITY

VETA is operating from a 236,806 sq.ft total multipurpose plant space and 3 privately owned plants located in Athens and Thessaloniki. We are in position to deliver a full range of end-to-end manufactured products and engineering services including laser cutting, punch pressing, folding, panel and tube bending, tube laser cutting, machining, welding, fabrication, powder coating as well as assembly.

Adding to that, our software capability to monitor in real time, the status of an order, the status of an article in an order as well as the operation that the article is in, provides with the transparency needed to avoid unecessary downtimes. Batch traceability per operation and per article, runs live as well.

We have maximized our manufacturing operations to exceed customer expectations

Our vertically integrated operations, have allowed us to manufacture products and offer fabrication services that meet the quality requirements of the spec. Our industrial operations sites are designed to comply with the latest European regulations and are regularly monitored by independent third party organizations. Our work is carried out under environmental as well as health and safety standards. Effective manufacturing operations are being supported by the VETA planning module. A system which monitors all 42 manufacturing operations and proactively feeds the planning team in potential operational and capacity bottlenecks.

FROM ENGINEERING TO PROTOTYPING TO FABRICATION

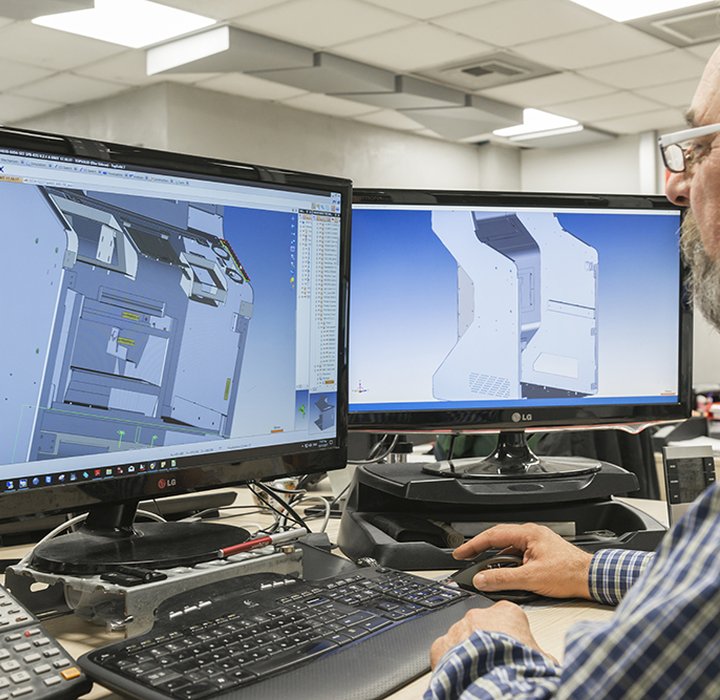

VETA is in a position to offer a complete services scope, from value engineering, process optimization, product development to a turn key manufacturing production of over 42 operations. An ERP-MRP software specifically built in 2003 and constantly being developed since then, is the key factor to maintaining a precise operational flow.

With 18 in total, 3D CAD licences, our team of engineers, all working on a PDM server, are in position to assist in projects of different levels depending on the outcome requirement.

Significant increase in manufacturing capacity

To capture growth opportunities in the international manufacturing market, which is driven by increasing demand for reliability, credibility, trust and integrity, we have expanded our manufacturing capacity to exceed customer expectations, implementing a 5 year investment plan. VETA has a manufacturing capacity via newly acquired machinery, an investment that exceeded 8,500,000 €. The implementation of an ongoing Continuous Improvement Strategy which started in 2013, has driven VETA on a different operational level. VETA has become more than it was, because its people have become more than they were.

STATE OF THE ART TECHNOLOGY

We employ cutting-edge technology to improve our production capacity through operational efficiency and effectiveness. VETA features state-of-the-art equipment, placing the company as one of the manufacturing companies in Europe offering a multitude of technologies. VETA is able to provide quality manufacturing services together with quality interpesonal relations. Better business means better relations. Better relations with our employees means better relations with our customers.

WE SUPPORT YOU WITH 55 CNC MACHINES

16 laser cutting machines • 9 Machining Centers • 1 Water-jet cutting machine • 4 Robotic welding stations • 12 manual welding stations • 3 punching machines • 4 CNC Lathes • 2 Tube laser cutting machines • 12 press brakes • Salvagnini Panel Bender• 3D Laser Marker • CNC Cylinder • 2 Electrostatic Powder Coating Units • Assembling & Packaging

INNOVATION EXPANDS OUR REACH

At VETA we believe that Industry 4.0 is here. Technology together with an updated and well educated personnel, is at the heart of our business model. Efficiency, effectiveness as well as responsiveness, is a prerequisite at today’s world.

By using the latest technology and optimizing our team skills, we are able to address demanding or complex projects in order to offer high-end bespoke services.

PLAN YOUR GUIDED VISIT TODAY

Plan your visit to take a guided tour at VETA’s industrial manufacturing and operations center in Athens. Any such guided tour, will get you acquainted with our facilities as well as an understanding of the production methodology used in multiple levels. Contact laser@vetasa.gr to schedule your visit at VETA!